We look forward to your inquiry and to the possibility of proving our expertise.

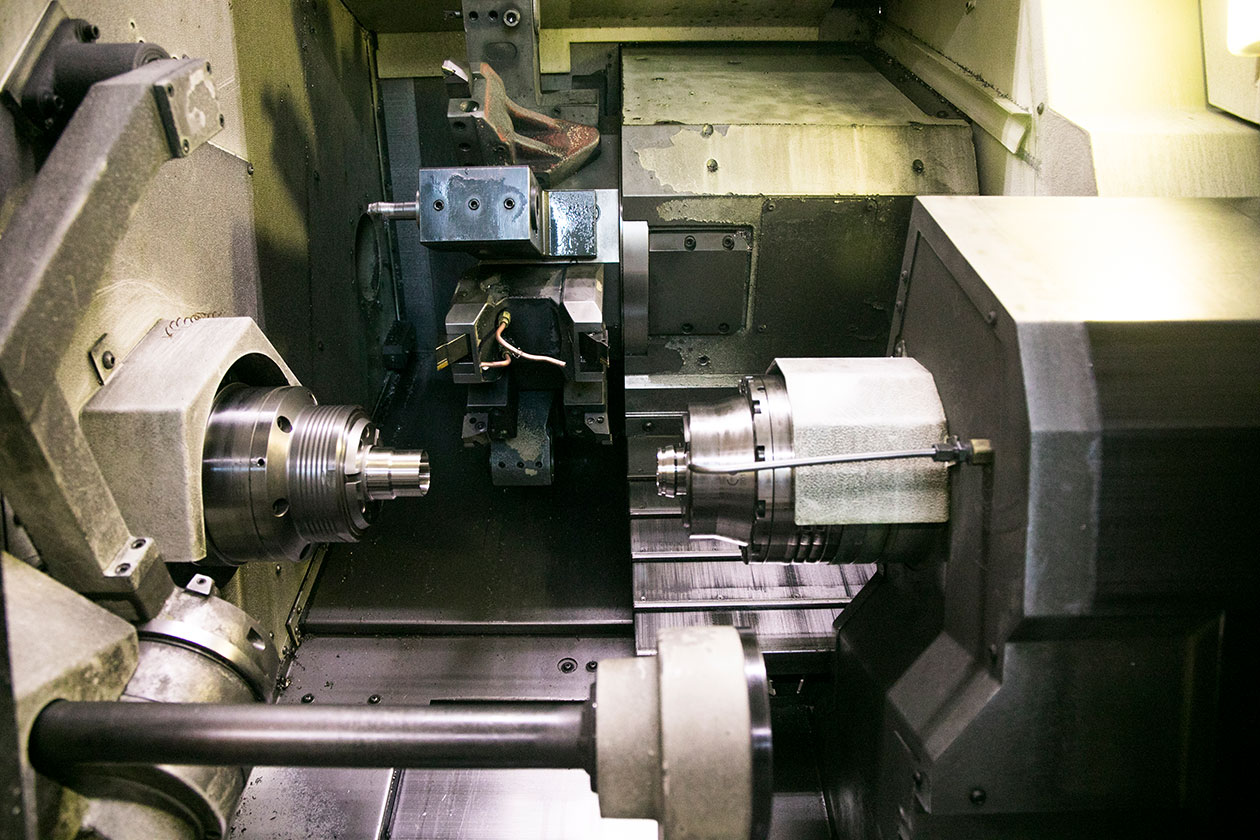

IN OUR MODERN PRODUCTION FACILITY,

we employ nine CNC systems.

Our strength lies in the production of stainless steel and steel in the diameter range of 16 mm to 200 mm.

A high degree of automation as well as proven material and tool management enable us to manufacture a wide range of products from prototype stage to series production.

We mainly rely on two types of loading systems. As far as the product allows, large parts are first sawn on our saws, which are equipped with a feed system. The parts are then inserted into the machine by robots and processed. Other parts are processed directly from the raw material rod by means of a feeder. About half of our production range – with increasing tendency – can be completely manufactured in only one process step, thus leading to drastically reduced throughput times and shorter delivery periods.

However, not all of our articles are suitable for automated production. These parts are manually fed into the CNC machines by our skilled staff.

Furthermore, a thorough process and programme documentation contributes to ensuring the consistent quality of our products.

Quality assurance and product inspection are continuously carried out by means of calibrated gauges and measuring instruments, according to the requirements of ISO 9001. In addition, our aim is to establish individual thread inspections, which would allow us to immediately locate potentially defective fittings.

Low reject and complaint rates have convinced several customers to have our fittings delivered directly to their construction sites. Our customers place great trust in our quality inspection and know that the products ordered can be used straightaway.

Apart from quality, the right material is another key factor. We therefore practise single-batch production of your articles, which can be proved by corresponding material certificates.

As part of our service, we can also provide you with the related inspection certificate (EN10204) upon request. With our marking laser we can mark your articles in accordance with the pressure equipment directive, including data such as nominal size and any other data you may request.

In case the inspection certificate is not sufficient for your needs we will be happy to restamp your article for you.

We look forward to your inquiry and to the possibility of proving our expertise.